About us

We are makers, made in California

Lightsmith laser was founded by brothers Seth and David Newsome are longtime members of the Bay Area maker community. We grew up in a family of makers with a carpenter father and an avid sewing and gardening mother. Some of our favorite memories growing up were hand making projects with our parents.

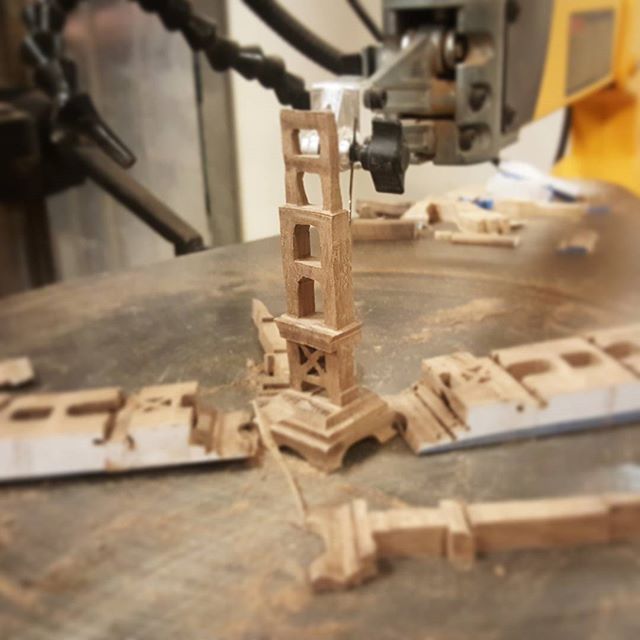

We took our making to a whole new level when we started working in Bay Area makerspaces, with Seth specializing in woodworking and laser engraving, and David specializing in CNC machining and prototyping. We love to combine the best of traditional craftsmanship with modern technology to create custom products, projects, and artwork for the community. We especially love working with fellow entrepreneurs to help realize their vision through prototyping, early stage manufacturing, and adapting designs to digital fabrication.

Seth Newsome - CWo (Chief wood officer)

Seth likes wood, It's no secret, Whether working or playing, he can usually be found hanging around the woodshop carefully cutting out crafts, furniture, signs, and more. He has a special place in his heart for hand tools and traditional craftsmanship, but he's also very comfortable with modern digital design and machining.

Dave Newsome - CFo (Chief Fabrication Officer)

Dave works stubbornly to make things as efficiently as possible, he likes working on hard projects with hard materials. He is very fond of the precision of digital machining, including CNC routers, laser cutters, and 3D design. When presented with a problem he will devote 100% of his focus to solving it.

Our work

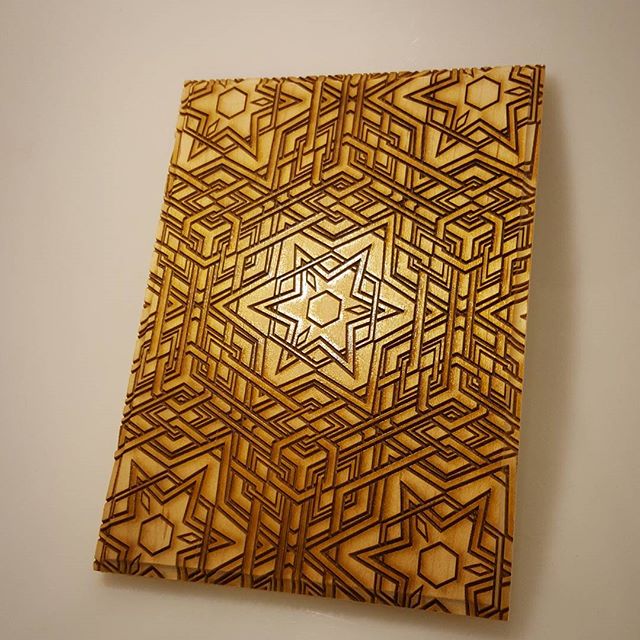

Here is a sample of some of the work we have done for ourselves and for our clients. Not just limited to laser cutting and engraving, we are heavy into woodworking and all sorts of other projects as well.

A prototype over-glasses style face shield

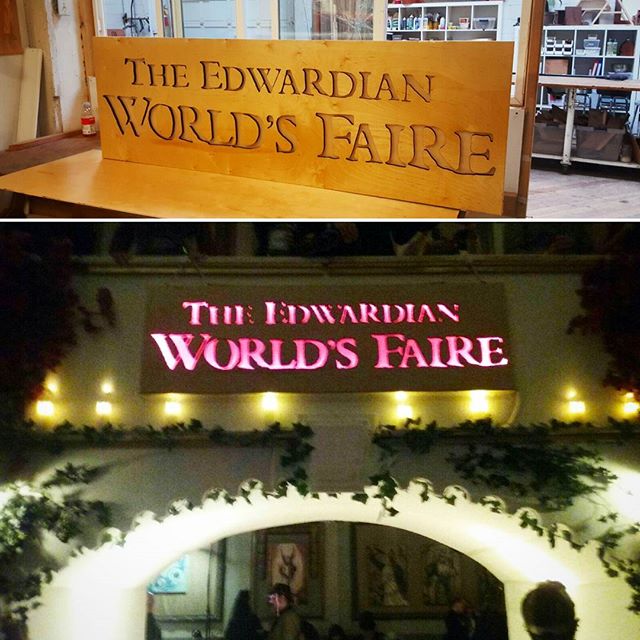

A small tabletop sign

A large internally lighted event sign for the 2018 Edwardian Ball

A custom catering cart and lighted sign, all wood and plastic work made by Lightsmith

An accent wall with fire engraving for Oakland based Total Health Dental Care

A large wood and acrylic sign made for Oakland based Total Health Dental Care

Trade show display made for Prophet Cannabis

Laser engraved skateboards produced for Oakland based artist The Laser Nerd

A special edition board game

Custom made speaker set with amplifying geometry

Get started

Use the form below to describe your project, as well as send us any design files, photos or documents. You may also email us directly at hello@lightsmithlaser.com.

San Francisco, CA 94107

Getting started

In order to get started, contact us with the following information

A description of the project

The materials to be cut or engraved

Any digital files you have - photographs, scanned images, raster files, vector files, etc...

Details on materials and file preparation is listed below. If you already have files prepared send them to hello@lightsmithlaser.com

Materials

Natural wood

Plywood, MDF, Wood Products

Paper products

Acrylic plastic

Other materials

Engrave only, no cutting

Materials we CANNOT CUT

When cut or engraved with a laser, these materials either do not work with our technology, release toxic hazardous gasses, or release chemicals which can damage the insides of our machines. We will not accept these materials for cutting or engraving. If you are not sure what a material is made from we will try to identify it, and may even offer a test cut, but we reserve the right to refuse any "mystery materials" that cannot be identified.

Design guidelines

We can work with anything from cocktail napkins to professionally produced digitial files. That said, it's faster and easier for everyone if your designs can conform to the following formats.

Experts only: If you need help with design contACT US AT HELLO@LIGHTSMITHLASER.COM

Here are some guidelines on how to best prepare files for us to give you a fast estimate. If you don't understand the terms used below don't worry - we will help you prepare any digital file for proper laser cutting or engraving.

File types and units

File types: For laser cutting and engraving we primarily use Adobe Illustrator (.ai) and Corel Draw (.cdr), .SVG 1.0, and .DXF

Units of measure: Standard or metric units can be used in your file. If you are submitting a precision technical file it is helpful to also include a reference object - for example a 1 inch circle or square - used to check for scaling errors.

Vector files

If your file was designed in Illustrator, Coreldraw or CAD software and consists of lines and curves - chances are it's a vector file

Cutting vectors - Vector lines that are supposed to cut through the material

Please make all similar cutting vectors the same color. If you have special instructions on how to process your file or how to order different colors please include this information when you contact us.

Both cutting and scoring vectors should be hairline / 0.001" thick

Scoring vectors - Vector lines that are supposed to make a mark or score line, but not cut through the material

Please make all similar scoring / marking vectors the same color. If you have special instructions on how to process your file or how to order different colors please include this information when you contact us.

Both cutting and scoring vectors should be hairline / 0.001" thick

Raster fill / raster lines - Fills and vector lines that you want to engrave on the surface of the material. If you desire a specific darkness, depth or other effect please include instructions when you contact us.

Raster files / Photographs / other artwork

If your file is a photograph, scanned image, .JPG, .PNG, .PS or any other raster based image

Resolution - Include the highest resolution of your image possible. Even if your engraving is not detailed anything up to 1200 DPI will improve the results of our work.

Contrast - For photographs and artwork high contrast images work best. If your image is not high contrast it may still be laserable, but may require additional processing to be laser ready.

Photographs should be well lit and the subject of the photo should stand out from the background for best results

Artwork with subtle gradients and color shifts may require modification to properly show up using laser engraving. We can discuss your options in your initial consultation.